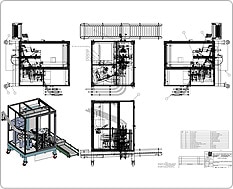

U-bolt Assembly Machine Assembly & Fabrication

Designing and building machines is one of our many expert services. When a marine industry client had a problem, they turned to JB Tool, Die & Engineering, Inc. for an answer. Beginning with the client’s concept, we engineered a machine that would automate the assembly of nuts onto variable length U-bolts. Using CAD modeling as a first step, we used a variety of our in-house processes, including CNC turning, machining, grinding and welding. Our highly trained automation staff built and programmed the machine’s control system. Once the machine was assembled, the finished product was fully tested and delivered to the client.

The operation of this machine involved creating a multi-step process to produce the final U-bolt assemblies. In building this machine, we worked to tolerances of ±.001″ to maintain that all components would perform up to our high standards.

Additional details on this U-bolt assembly project can be found in the table below or contact us for more information.

U-Bolt Assembly Machine Project Highlights

| Capabilities Applied/Processes (Machining, Molding, Welding, etc...) | Engineering Turning Machining Grinding EDM | Welding Heat Treat Controls Build & Programming Assembly and Testing |

| Tightest Tolerance | +/- .001" | |

| Industry for Use | Marine | |

| Standards Met (Customer Supplied Print, ISO, ASTM, etc...) | Customer Specifications | |

| Product Name | U-Bolt Assembly Machine | |

| Project Scope | Develop a machine to automate the assembly of nuts onto variable length U-Bolts and validate the assembly |

|

| Design Work (CAD Modeling, FEA, etc.) | CAD Modeling, FEA | |

| Operational Description |

|

|